Do you want to take advantage of 3D scanning to speed up your dimensional measurements? If you already own a traditional Coordinate Measuring Machine (CMM), you may have heard that you can retrofit it to convert it into a 3D scanner.

Do you want to take advantage of 3D scanning to speed up your dimensional measurements? If you already own a traditional Coordinate Measuring Machine (CMM), you may have heard that you can retrofit it to convert it into a 3D scanner.

While this kind of CMM retrofit seems appealing, there are several items to consider before going ahead with such a project:

- Only one function is available at a time: When a CMM is retrofitted with a 3D scanhead, it can be used as a 3D scanner but it can no longer be used as a touch probe device while in scan mode. Switching from touch probe to 3D scanner mode can also be time consuming and usually requires a calibration step before new measurements can be made. This limits the potential efficiency gains of adding 3D scanning capability.

- CMMs were not designed to be converted to a 3D scanner: A CMM that integrates CMM motion software, 3D scanner data acquisition software, and analysis software is not as easy to use as a 3D scanner designed from the ground up. Indeed, some of the benefits for 3D scanning are lost when the scan path needs to be painstakingly programmed using the CMM motion software which was designed for touch probing.

Standalone 3D Scanners Complement CMMs

Most manufacturers will find that it is more efficient to supplement their existing CMM with an additional standalone 3D laser scanner. 3D scanners give users the ability to choose the right inspection tool for the job, and to gradually transition existing inspection projects from the CMM to the 3D scanner. A 3D scanner offers a net gain of total inspection capacity from the start.

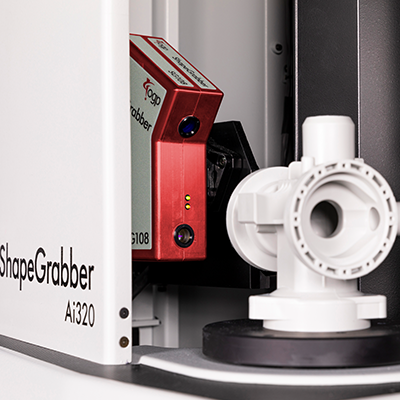

Automated 3D laser scanners, like those offered by ShapeGrabber, are purpose-built for laser scanning and will complement your existing CMM. Our 3D scanners are designed to handle the compound curves and other complex shapes that are precisely the type of features CMMs struggle with. If you are considering a CMM retrofit and have questions about the benefits of a standalone 3D scanner, contact us!