The injection-mold tryout provides mold makers with an important means of testing and documenting the quality of their product. The tryout is used to prove out the mold, and provides an opportunity to repair any defects before it is shipped to the customer.

The injection-mold tryout provides mold makers with an important means of testing and documenting the quality of their product. The tryout is used to prove out the mold, and provides an opportunity to repair any defects before it is shipped to the customer.

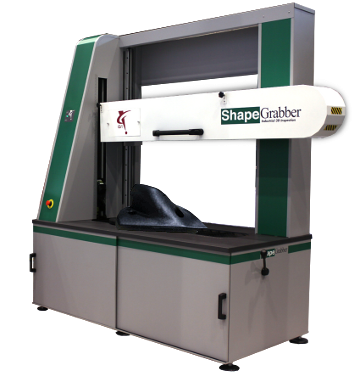

An automated 3D scanner such as an industrial-grade laser scanner from ShapeGrabber is a valuable tool during the tryout process, specifically to help characterize the complete shape of parts produced by the mold. This provides proof that the mold meets the requirements. It also significantly speeds up the troubleshooting process when problems are identified. Our 3D scanners make this process fast and simple.

Quickly Verify Molds

One method used to verify a mold is to measure the mold itself, and ensure that it conforms to the designed dimensions. This can be time consuming and difficult due to the typical size and weight of the mold. Also, mold specs are not in themselves critical, since they are only derived from the specifications of the parts they are designed to mold. During a mold tryout, on the other hand, the mold would be inserted into an injection molding machine and used to produce many parts. If the parts produced are consistently good, then the mold is deemed acceptable.

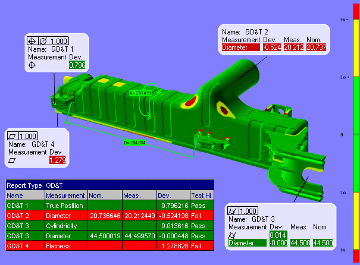

TThe problem with mold tryouts is the time required to measure the plastic parts produced. This is where ShapeGrabber comes in. A ShapeGrabber industrial 3D scanner will perform fast, accurate, and detailed measurements of the molded parts in minutes. The scanner collects millions of data points, and compares these directly to the part’s 3D CAD model. Any deviations are immediately shown, allowing for quick acceptance or troubleshooting of issues. It is also fast and easy to verify molds using a variety of materials. By comparing the 3D scans to each other as well as to the part’s CAD model, mold makers can readily see how different materials behave in the same mold.

TThe problem with mold tryouts is the time required to measure the plastic parts produced. This is where ShapeGrabber comes in. A ShapeGrabber industrial 3D scanner will perform fast, accurate, and detailed measurements of the molded parts in minutes. The scanner collects millions of data points, and compares these directly to the part’s 3D CAD model. Any deviations are immediately shown, allowing for quick acceptance or troubleshooting of issues. It is also fast and easy to verify molds using a variety of materials. By comparing the 3D scans to each other as well as to the part’s CAD model, mold makers can readily see how different materials behave in the same mold.

Troubleshoot Issues

he high data density that a ShapeGrabber 3D scanner provides, coupled with the visual nature of the data analysis, helps to pinpoint the cause of any deviations and make issues with molds obvious. The data analysis may also suggest problems that are not associated with the mold – such as problems with raw materials or a flaw in the molding process.

Please contact ShapeGrabber to discuss how an automated 3D scanner can enhance your injection mold tryouts.