Inspection for Design

Designers can use ShapeGrabber 3D scanners to complement 3D modeling and CAD systems during the product design process.

Designers can use ShapeGrabber 3D scanners to complement 3D modeling and CAD systems during the product design process.

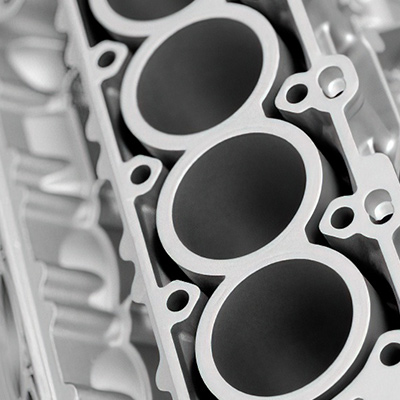

ShapeGrabber systems can be used to scan early prototypes, enabling 3D inspection to quickly validate the complete part geometry. This allows for faster troubleshooting of problems and provides better feedback into the manufacturing process, reducing the complete design life cycle.

ShapeGrabber’s portable scanners are excellent tools to troubleshoot form and fit issues on mating parts.

Unlike traditional methods that rely on the inspection of a few pre-programmed points, our non-contact laser scanner technology captures millions of data points to accurately represent the true geometry of your complex part. Our 3D laser scanners are fast, easy to use and don’t require you to write a computer program before scanning your part.

ShapeGrabber inspection for design solutions let you:

- Design unique products: Innovate beyond traditional boundaries and limitations found in design and CAD software.

- Gather design feedback: Examine accurate 3D part models to gather accurate and timely feedback on your prototypes.

- Rapidly verify, render, and compare new product designs.

- Troubleshoot your manufacturing process to reduce the length of the design cycle.