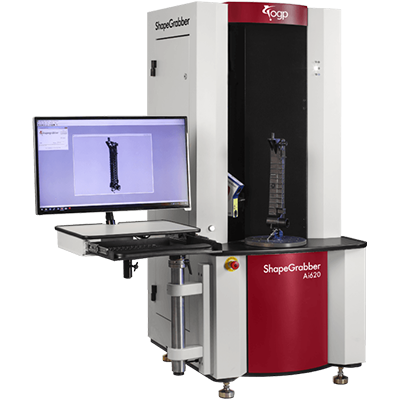

Ai620 Automated 3D Scanner

The ShapeGrabber Ai620 3D Scanner is a floor-mount system that delivers unprecedented levels of speed, data quality and resolution. It is easy to use and includes a robust enclosure with an integrated, optional monitor stand.

The ShapeGrabber Ai620 3D Scanner is a floor-mount system that delivers unprecedented levels of speed, data quality and resolution. It is easy to use and includes a robust enclosure with an integrated, optional monitor stand.

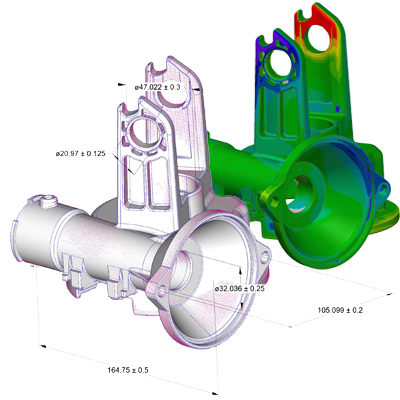

ShapeGrabber’s Ai620 3D scanner is a precision, metrology-class 3D scanner. The Ai620 measures the complete surface of complex shaped plastic, metal, and 3D printed parts in minutes with a high density of data points.

The Ai620 is easy to use and highly automated. After an initial scan, the same scanning parameters may be used for subsequent parts, delivering consistent results irrespective of operator skill or experience.

The Ai620 is fast. Data capture rates range from 155,000 pts/s to upwards of 1.5M pts/s. But that does not tell the whole story. It can be setup for new parts very quickly. The precision turntable repositions the part for additional scans accurately with no need for targets or software alignment, and the automation makes all this work seamless. What this means is not just fast data, but fast time to results.

The Ai620 derives its inherent accuracy by combining a highly rigid and stable mechanical structure, high precision vertical and rotary motion, state of the art calibration, and the leading-edge optics of the included scanhead. The result is high quality data, delivered quickly and reliably. Our automated scanners provide:

- Ease of use – no need to write special code to scan each object

- Speed – fast and simple to scan a part without complicated, time consuming orientation and alignment processes

- Efficiency – significantly reduce the time required to completely scan a shape, reducing the cost associated with executing the job

- Visualization – easy to interpret and share results to quickly identify and understand part issues

Features & Benefits

- Very fast: reduce your inspection time to minutes instead of hours

- Turnkey: all you need is your part

- Totally integrated: acquire, align, and inspect using a click of the mouse

- Compatible with a wide variety of materials and colors

- Easy to use: requires no software alignment

Included with Every System

- Scanning platform that includes a high precision linear rail, rotary table, motor and controller

- SG198 Scanhead

- ShapeGrabber SGCentral™ software for data acquisition, image display and file manipulation

- Powerful CAD-class workstation

- 1 year parts and labor warranty

- 1 year technical support and software maintenance contract

Specifications

Physical Characteristics

- Footprint: Width: 850mm, Depth: 1000mm, Height: 1870mm

- Work Surface: Floor mount

- Weight: 400kg

- Power Requirements: 100-240 VAC, 50/60 HZ, 1 phase, 500 W

- Laser: CDRH Class II / IEC Class 2M

Performance Overview

- 600mm of vertical motion

- High precision rotary table automatically reorients part being scanned a full 360 degrees

- Data capture from 155,000 to 1,500,000+ points/sec

- Cylindrical scan volume of 600mm high x 185mm in diameter.

- Optional tilt axis rotates scanhead to a downward look angle of 25 degrees.

- Laser: IEC Class 2M